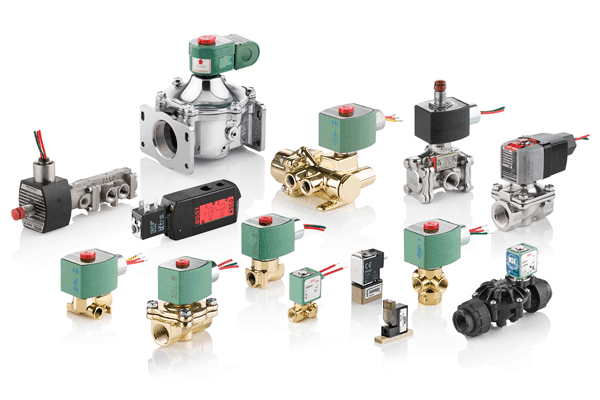

Prior to starting your solenoid valve selection process, make sure you are backed up with enough information about the application. This article will show you the key areas of solenoid valves.

It is important that you know which elements are significant to your application. Make use of the filter feature on webshops to help you find the right valve that suits your requirements. Or, you can ask further assistance from your valve supplier. For sure, they can provide you the best options available.

Moreover, whether you’re new to the valve industry or not, this article will surely benefit you in every way, especially with your journey of finding the right solenoid valve for your application.

Solenoid Valve: A Short Overview

Before we dive into the comprehensive guidelines, let’s get to know the simple definition of solenoid valves.

Solenoid valves transmit electrical signals and turn on or off the supply for air going to the pneumatic linear actuator. Standard solenoid valves comprise of a piston, plunger, electromagnetic coil, valve body, and piston spring. During the application of electrical power to the electromagnetic coil, the piston will be connected and will cause movement inside the valve.

This will then opens or closes the different ports inside the valve releasing air supply to control the pneumatic linear actuator. When removing the electrical support, the spring reverts the piston to its initial position and turns the air supply off to the pneumatic linear actuator.

Comprehensive Selection Guide

As previously mentioned, when choosing the right solenoid valve it is important to gather all relevant and necessary details. Below are the most essential guidelines you need to bear in mind during your selection process.

- Take note that solenoid valves should not be exposed to dirt as they are highly sensitive. They will only operate with clean air or fluid.

- Solenoid valves that are controlled indirectly need a pressure differential that is permanent and should be around 0.5 bar to fully function. Hence, you can never utilize indirectly controlled valves in a closed system with a low-pressure inlet. Both semi-direct and direct-controlled valves work with a differential pressure from 0.

- Compatibility plays a very important role. Therefore, make sure that the medium used and the temperature is suitable with the valve materials like the seal and the body.

- Solenoid valves close and open at a fast pace. Using them improperly may lead to pressure drifts in the entire circuit.

What are Solenoid Valves Commonly Used for?

- They are often used in hydraulic and pneumatic systems as fluid power in order to manage cylinders, power motors, and huge industrial valves.

- They are utilized in plants and factories where condensed air is not accessible.

- Solenoid valves are also used to regulate the entry of water in dishwashers and washing machines.

- They are essential in the medial area especially when a device needs to be very accurate and on point.

- They can be used for different industrial applications, such as calibration, on/off regulation, pilot control, process control, and other equipment applications.

- There are other solenoid valves are used at a more innovative process depending on the fluid flow, input signal, and pressure.

Different Standard Solenoid Valve Components

There are two major parts that a solenoid valve is comprised of — the valve and the solenoid.

- Solenoid – A wire made of cylinder coil, which serves as an electromagnet in the event electric energy enters through.

- Valve – Serves as a regulating device that manages the fluid flow by opening, closing, or covering some pathways partially.

Other essential parts are the following:

- Solenoid tube – Serves as a guide channel of the plunger which is shifted in a magnetic way. Solenoid tube is made of a stainless steel cylinder in which the other end is covered. It has a solenoid coil attached perfectly on the other side of the tube.

- Valve body – This is the central part of the valve that includes seats, ports, and pathways which allow movement of liquids when the valve is energized or not.

- Plunger spring – A return spring capable of holding a shifting plunger in position. It will revert to its original position when not active.

- Moveable plunger – A coil that is electromagnetically attached to stainless steel. The plunger is attracted by the magnet coming from the magnetic field of the solenoid.

- Electromagnet – It consists of a copper winding together with a magnetic chain. When activated, it produces magnetic energy that attracts the plunger.

- Seat seal – Utilized to close or open a valve pathway and is situated on the plunger.

Solenoid Coils

These coils convert electrical power into linear energy. Typically made of aluminum or copper wire wrapped around an arched form. A valve plunger is also placed within the coil. When electric energy starts to flow inside the coil, the magnetic flux lines will move the plunger into an electromagnet, thus producing a magnetic force. As for coils, there are two types of solenoid valve coils used in the application.

- Enclosed coil – This consists of a copper wire twisted around a spool. The enclosed coil is an ideal resin rather than a tape. It can be utilized in surroundings with an intense level of humidity and is made with sturdy wires for protection against sudden take-off.

- Tape bind coil – This comprises of conductor wire enclosed around a spool. The magnet wire (conductor wire) has a thin layer of insulation placed around it. The finished winding is covered for protection by another layer of tape for insulation.

Tape bind coils are ideal in applications with less harsh environments. They can be utilized for minimal productions, however, they have a lesser moisture resistance.

Solenoid Ports

Solenoid valves generally have two ports. These ports often come in a tandem situated in the center of the solenoid valve. The tank ports and pressure are attached while the service sockets are emptied. It is designed this way to maintain unloading of the system while service line isolation is still working. The rest of the ports are relatively connected so that supply will be turned off while allowing the load to shift wheel with the available flow to other applications.

Solenoid Valve: Principles of Operation

A magnetic force is made when solenoid valves receive the electrical current, which results in two forces countering one after another as well as delivering air straightly to a plunger spring within the coil. The coil has an essential seat to open in the event the solenoid coil is activated. When electric energy is taken out from the solenoid coil, a spring carries the plunger back to its closing position, hence the fluid flow will be cut off, depending on the valve blueprint.

Conclusion

Solenoid valves and their entire components are not that hard to understand. It’s just a matter of knowing the basics and the essential components as well as their impact on your application. What you have read will surely help you with your selection process. With the increasing amount of applications in different industries, it’s no wonder the demand for solenoid valves together with other valves are rising as well.

Also Read- Volvo Offers a New Advanced D13TC Engine